Many of the power system software packages are effective and useful in validating, optimising and carrying out the necessary calculations for new power system designs. For this purpose they need to be flexible so as to cover the full range of possibilities before the design is settled.

Advances in programming however, mean there is now a ‘new kid on the block’; bespoke power system analysis software. This approach introduces a new paradigm, promising to take software design techniques beyond its traditional design and consulting office setting to the plant’s operational, maintenance and management reports setting, where if properly applied it can be used to greatly enhance economic advantage.

Below outlines the five main benefits of bespoke power system analysis software.

1. Reduces the level of flexibility where it could be a disadvantage

If standard packages were used in an operational setting, flexibility becomes a drawback and may even be hazardous. Typically a power system model has hundreds of parameters which define the model configuration and the key system behaviours.

In a typical operating environment, where there are several people interacting with the model on a day-to-day basis, keeping track of the changes is a significant exercise, especially with regard document control logistics. The possibility for error is quite high and depending on how the model is used; an error could result in loss of production or dangerous operating conditions.

Customised power system software offers a solution to this situation. The idea is to reduce the level of flexibility - whenever it could be a disadvantage - so that the model reflects what is on site and ensures fixed equipment parameters (equipment ratings, impedances, connections, system topology) remain fixed (i.e. the software is designed so fixed parameters can’t be modified by the user).

2. The model can better reflect the real world

Customised software better reflects the real world, reducing the malleability of the model and significantly reducing the possibility for errors. This can yield significant benefits because it can be designed to reflect how the plant actually is, and the degrees of freedom of the model can be designed to be the same as the degrees of freedom of the actual plant.

The quality of the model in the sense of how accurately it reflects the real physical world can be made extremely high. Commercial packages sometimes have to compromise on quality because they must be designed to cover a large range of possible system configurations.

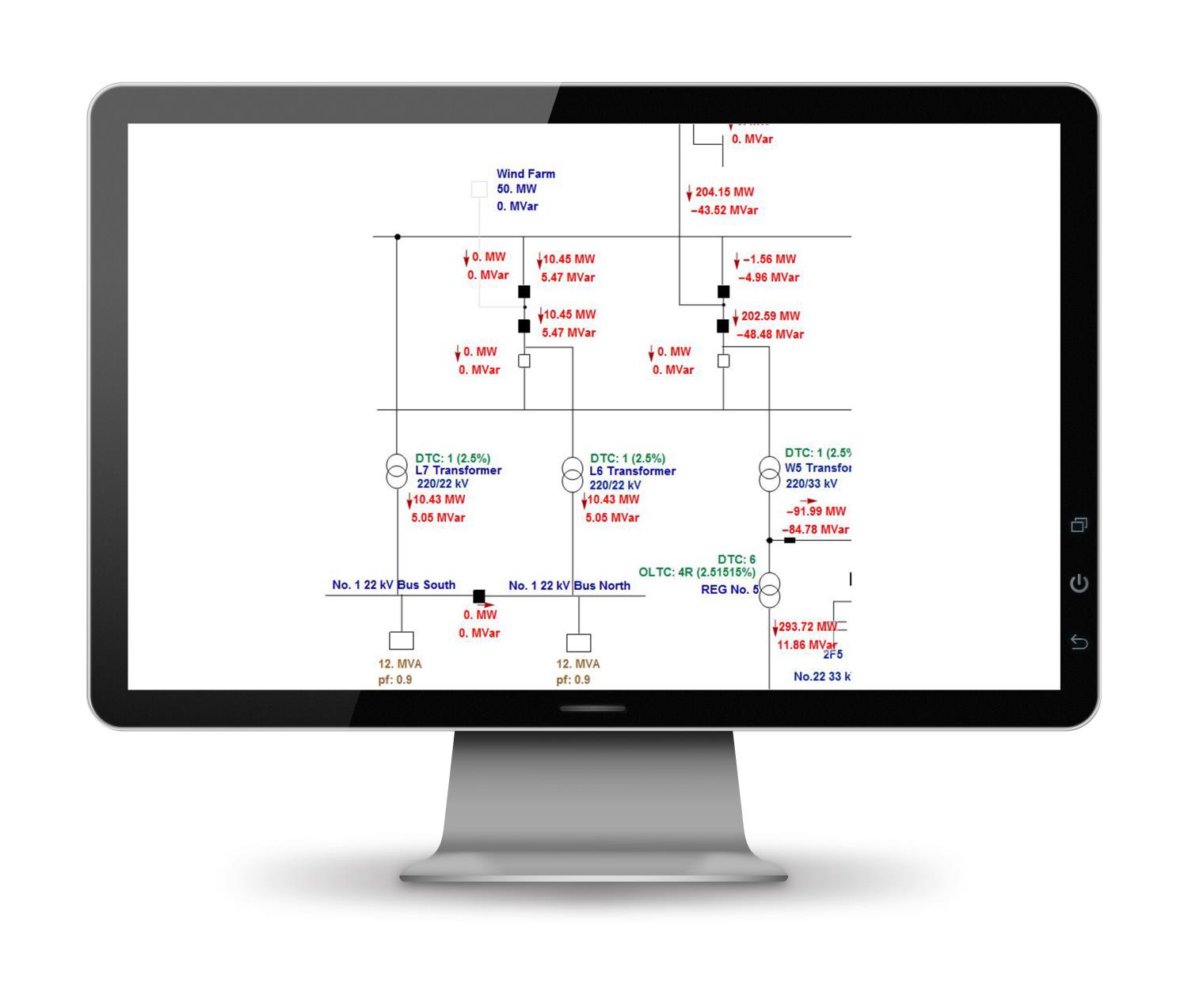

Figure 1 - Part of a bespoke power system model of an aluminium smelter

3. Cost is whatever is necessary and no more

Another benefit of bespoke software is cost. The complex software produced by the various software suppliers needs to allow for virtually any possible power system. As a result, a model of a typical plant only uses a small subset of the possible model subsystems, however when you use a typical power system analysis package you are paying for all that complexity even if it is not used.

Modern software techniques allow bespoke software to be rapidly created without expensive development costs, making them very competitive.

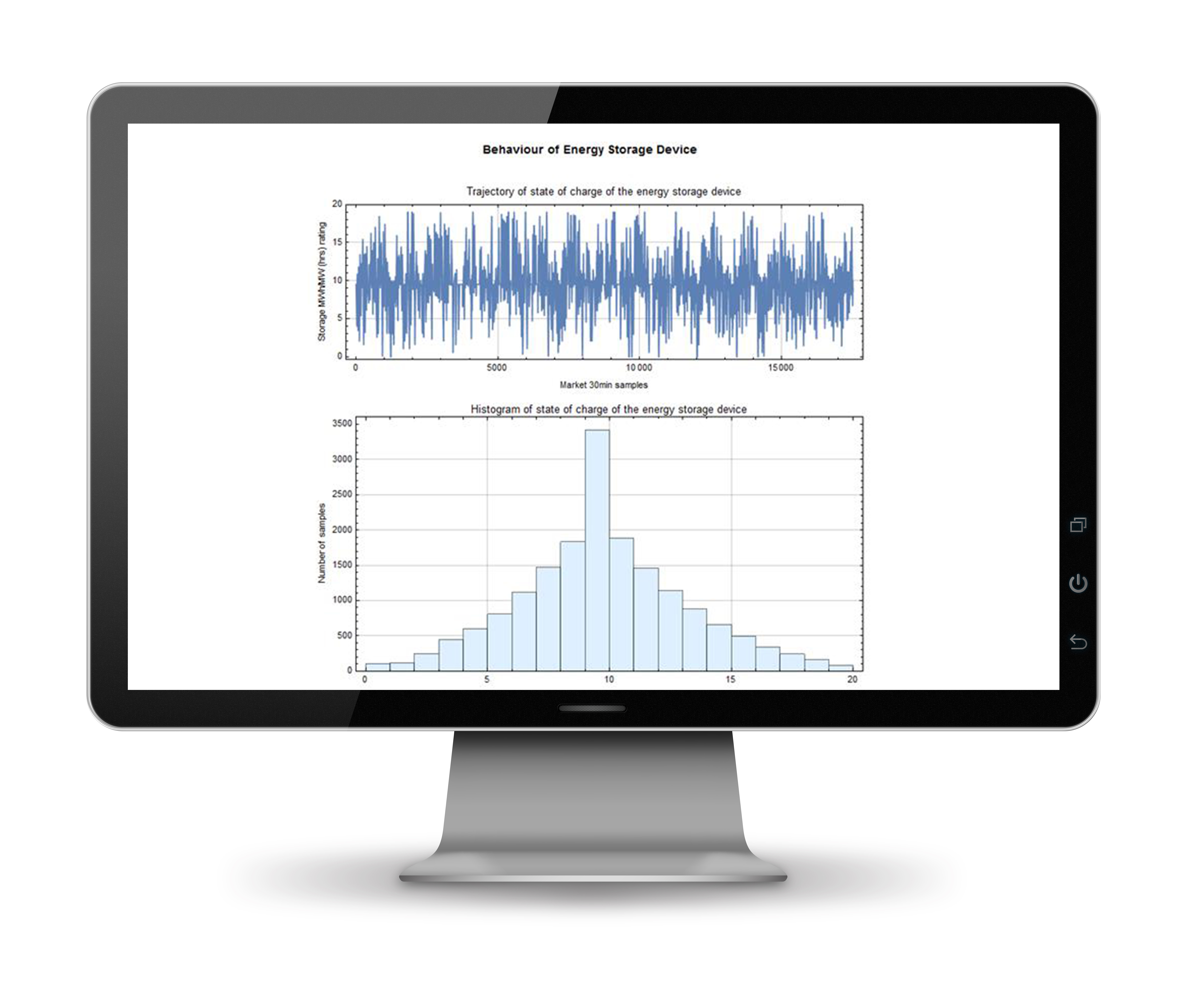

4. Can include the features required by new technology

Until now we have been espousing the benefits of reducing unnecessary flexibility in order to simplify the model and cut down on the possibility of modelling errors. However, for some plants the various models provided by commercial software may be insufficient. This happens when new technology is introduced which is not yet accounted for in the various packages.

For example when wind farms became common, the models for wind turbines were not often developed at that time. Similarly, the details of power invertors used on solar power installations were sometimes not well catered for in commercial power system analysis software.

The commonly available packages had to play catch up to represent the new technology. Sometimes the model is very simple but still not representable in a commercial package. For example in aluminium smelters, voltage regulating transformers have a very wide range which some commercial packages are unable to represent because such transformers are not typically used by power utilities.

Bespoke power system analysis software can easily bypass these issues. The customised software can be designed to model what is actually present and no more. This approach has all the advantages of being able to produce an accurate and representative model, and all the advantages of simplicity of operation which reduces the possibility of errors.

5. Easily cross discipline boundaries

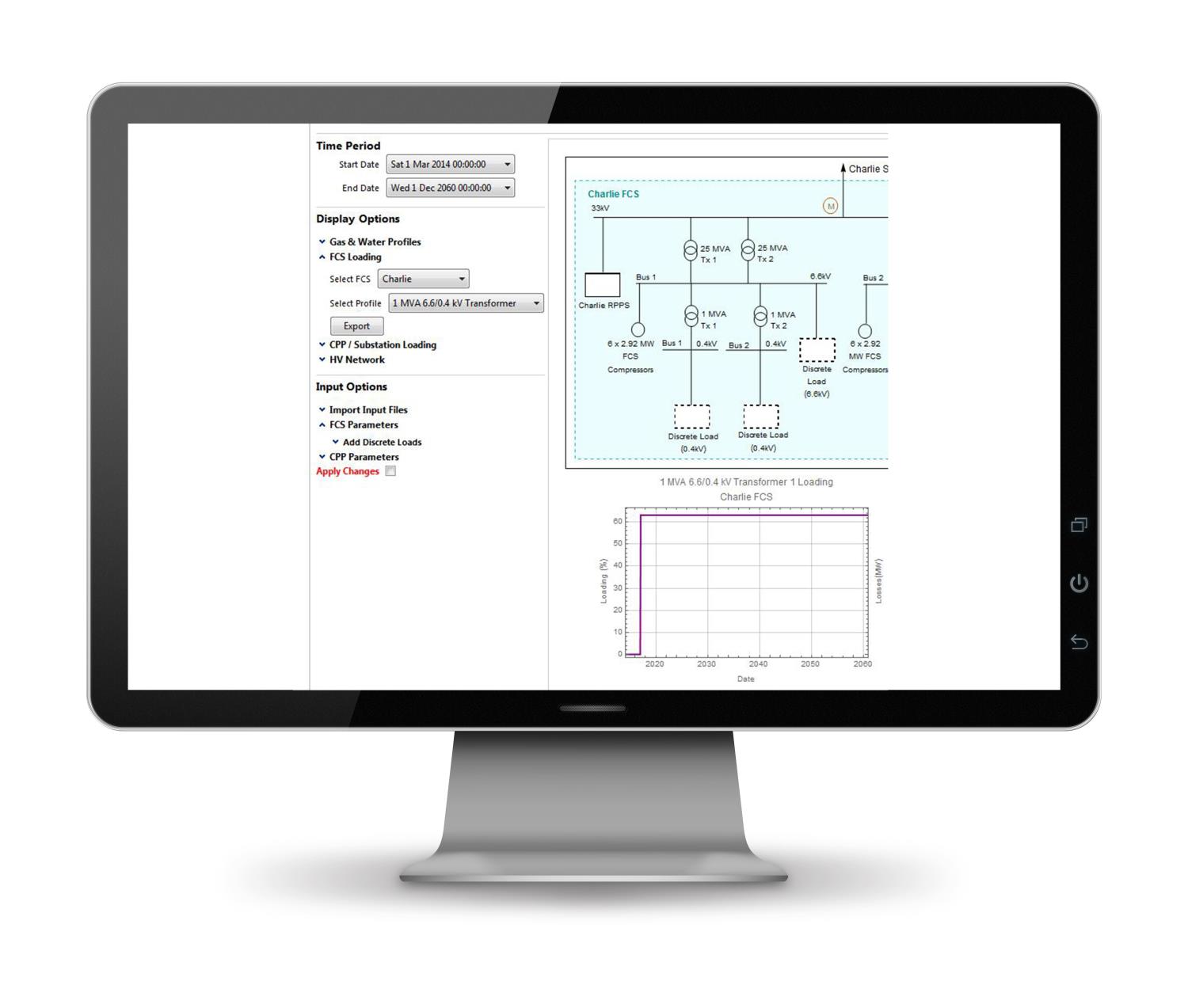

Another advantage of bespoke software is that it can easily cross discipline boundaries. The power system is crucial to most plants but it is invariably (except for power stations) an element of production, not the product.

Generic commercially-available power systems software typically only considers the power side of the system. Bespoke software can be designed to consider the production side as well. This allows operations to consider their plant in a more holistic way and make decisions based on all of the relevant information, not just a narrow discipline centric viewpoint.

Figure 2 - Part of a bespoke power, water and gas model of an LNG plant

There are of course pitfalls which need to be negotiated. You need to have good communication between the software developer and the end user. The end user should have a clear idea of what they want the custom software to do. Your software developer should have a broader education and experience in power systems than just someone who knows how to write the code. Specifically, they should understand the physics and economics of what they are simulating before they attempt to simulate it.

Figure 3 - Part of a bespoke model of a large-scale energy storage device

The sixth benefit - bespoke software can be easily transmitted

Didn’t we say there were five benefits? Actually, we can think of a few more which did not quite make it to the list.

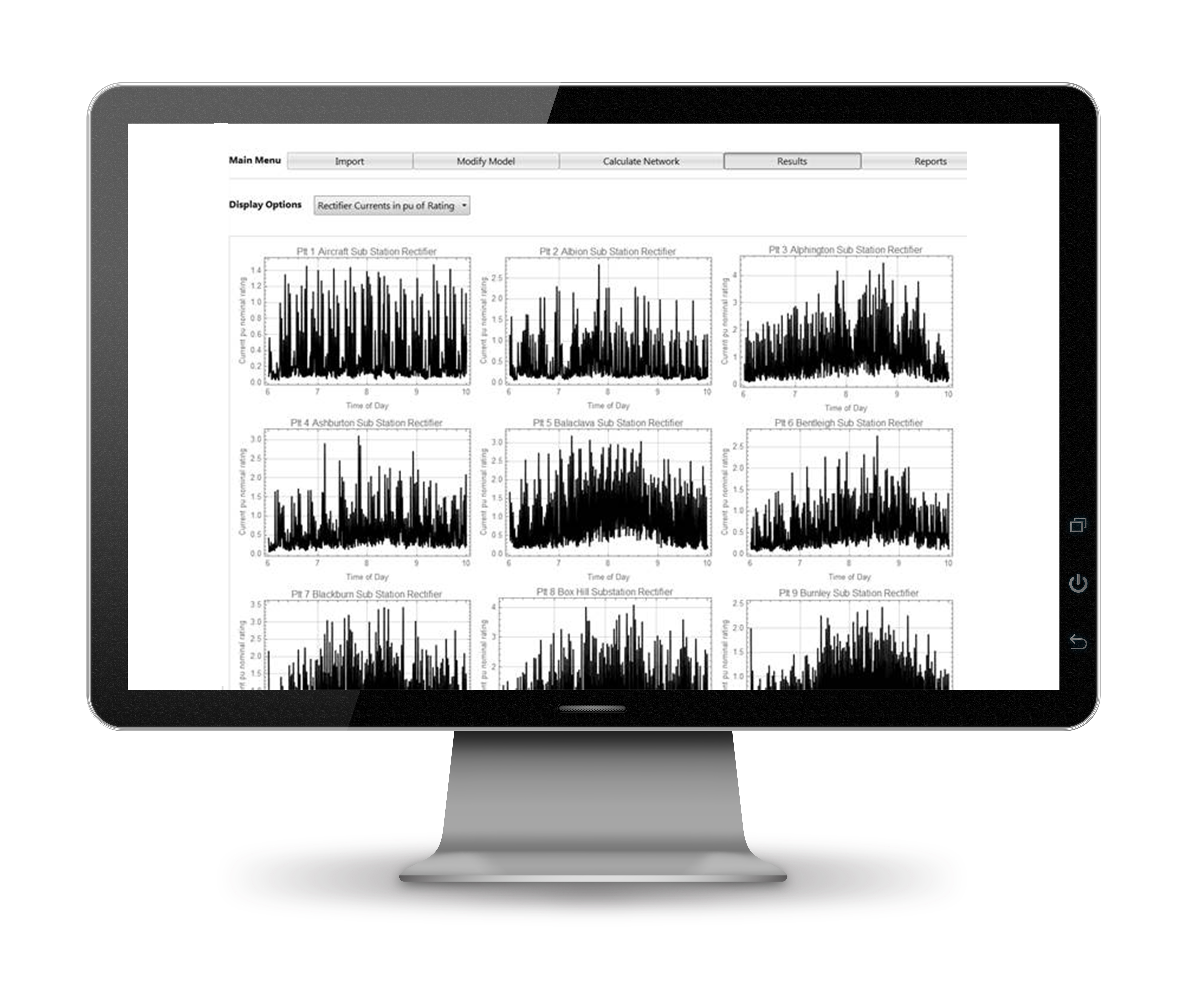

There is a late entry which we feel we could not leave out. Unlike the large, comprehensive software tools that require significant IT support to install and train personnel, many customised packages can be made small enough to attach to an email.

This opens up and extends the potential for remotely located teams to work closely with each other to obtain the best outcomes for a project. The new working paradigm for engineering is to not only produce documents and drawings, but also interactive models which are simple enough for non-specialists to understand.

Figure 4 - Part of a bespoke model of the Melbourne Metro system

While there will always be a place for complex software tools with extensive features to assist with concept and detailed design and development, there is also a place for custom-made tools, fine-tuned to specific plants and requirements to assist with plant operation.